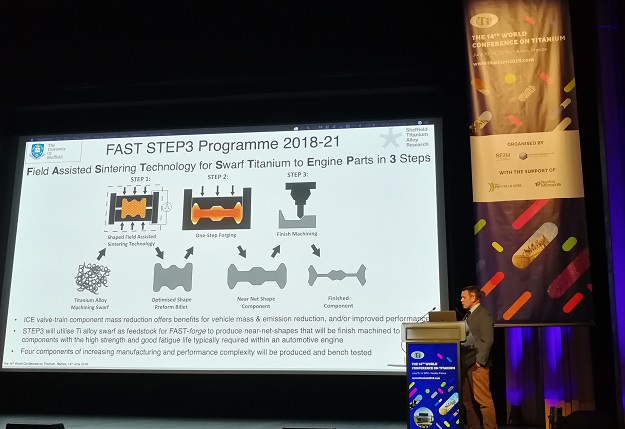

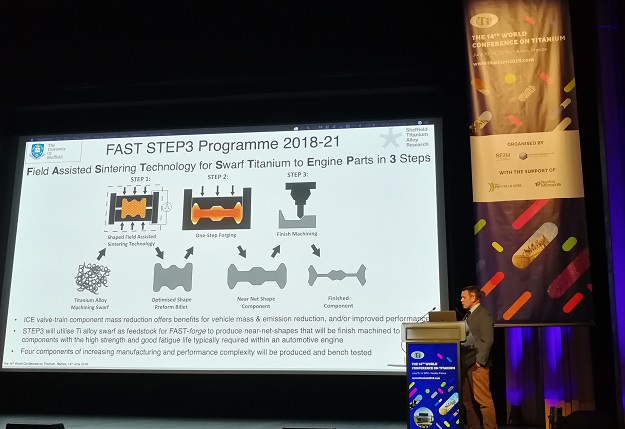

A FAST STEP3 project partner recently delivered a Keynote presentation at The 14th World Conference on Titanium on Friday the 14th of June in Nantes, France. Dr Nick Weston from the Sheffield Titanium Alloy Research group, based in the Department of Materials Science and Engineering at The University of Sheffield, spoke on “Exploitation of Field Assisted Sintering Technology (FAST) for titanium alloys”.

Dr Weston developed FAST-forge during his PhD; a cost-effective processing route that can turn titanium alloy powder/particulate feedstocks into a near-net-shape components with forged properties in just three steps. This is a drastic reduction from the conventional processing route, which can have over forty steps.

The Keynote covered the initial developments of FAST and FAST-forge processing for titanium alloys, and the exciting development of FAST-DB, where dissimilar titanium alloys can be diffusion bonded together. The current status, emerging developments, and challenges of FAST for titanium-based feedstocks were also presented, including case studies showing FAST being utilised to produce aerospace and automotive demonstrator parts such as rocker arms, turbine blades and brake callipers.

Ten members from the Sheffield Titanium Alloy Research group also attended the conference. They presented their cutting-edge research on titanium alloy machining, processing, and characterisation.